Updated: October 2025 | Reading Time: 8 minutes

Table of Contents

Table of Contents

- Why Roller Shutter Maintenance Matters More Than You Think

- UK Legal Requirements: What You Must Know

- How Often Should You Service Your Shutters?

- DIY Maintenance: What You Can Safely Do Yourself

- Warning Signs That Require Immediate Professional Attention

- Professional Servicing: What to Expect

- Seasonal Maintenance: Adapting to British Weather

- Common Problems and When to Call for Help

- Choosing the Right Maintenance Provider

- Conclusion: Protecting Your Investment and Your Business

As a business owner, your roller shutters work tirelessly to protect your premises, but when did you last think about maintaining them? Most business owners only notice their shutters when something goes wrong—and by then, it’s often too late to avoid costly emergency repairs.

A single emergency repair can easily cost over £1,000, while proper maintenance typically costs just £200 annually. More importantly, neglecting your shutters isn’t just expensive—it’s illegal under UK law and could leave your business vulnerable to break-ins, accidents, and hefty fines.

This comprehensive guide will show you exactly how to maintain your roller shutters properly, stay compliant with UK regulations, and avoid the nightmare of emergency breakdowns.

GET A FREE SERVICING QUOTE | 24/7 EMERGENCY REPAIRS: 0207 112 4849

Why Roller Shutter Maintenance Matters More Than You Think

Every day you delay maintenance increases your risk of costly problems. When roller shutters fail, they don’t just inconvenience you—they can shut down your business entirely. A shutter that won’t close at the end of the day leaves your premises completely vulnerable, while one that won’t open in the morning means you can’t serve customers.

The financial impact extends far beyond repair costs. Emergency repairs typically cost between £800-£1,500, but that’s just the beginning. You’ll also face lost revenue from business disruption, potential security breaches, and possible legal action if someone gets injured by faulty equipment.

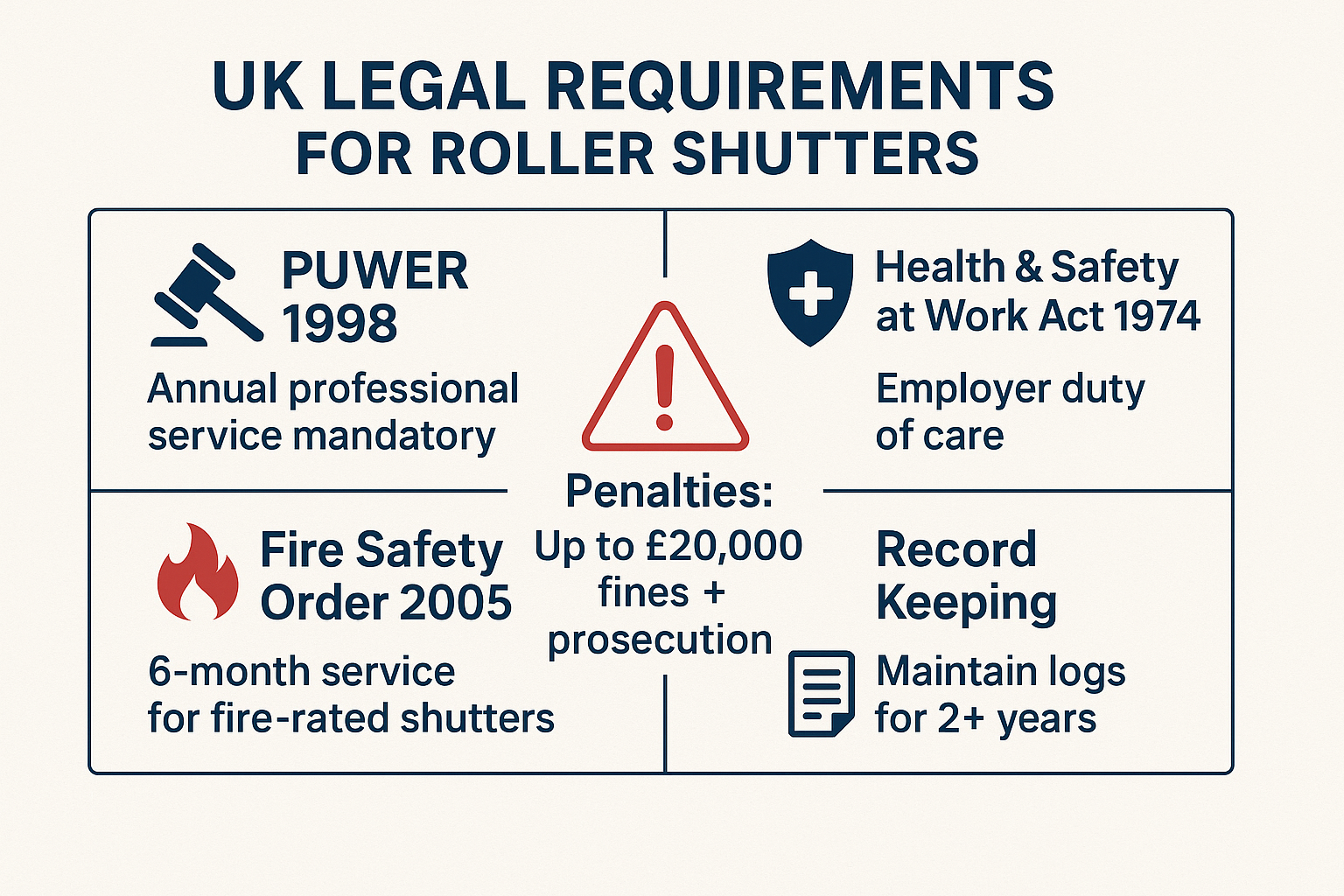

Beyond the immediate costs, poorly maintained shutters pose serious legal risks. Under UK law, you have a duty to maintain all work equipment, including roller shutters. Failure to comply can result in fines of up to £20,000, forced closure of your business, and even criminal prosecution if an accident occurs.

Insurance companies also take maintenance seriously. Most commercial policies require proof of regular servicing, and claims can be rejected if you can’t demonstrate proper care of your equipment.

UK Legal Requirements: What You Must Know

Understanding your legal obligations isn’t optional—it’s essential for protecting your business and avoiding serious penalties. The key regulations affecting roller shutter maintenance are straightforward but strict.

PUWER 1998 (Provision and Use of Work Equipment Regulations) requires all work equipment to be maintained in efficient working order with regular inspections by competent persons. For roller shutters, this means annual professional servicing at minimum, with more frequent servicing required for high-use applications.

The Health and Safety at Work Act 1974 places a duty on employers to ensure equipment safety for employees and visitors. A faulty shutter that causes injury represents a clear breach of this duty, potentially resulting in criminal prosecution.

The Fire Safety Order 2005 applies additional requirements to fire-rated shutters, mandating servicing every six months and immediate inspection after any fire alarm activation.

The documentation requirements are equally important. You must maintain written records of all inspections, services, and repairs for at least two years, though five years is recommended. These records must include details of the work performed, parts replaced, defects identified, and the qualifications of the person carrying out the work.

How Often Should You Service Your Shutters?

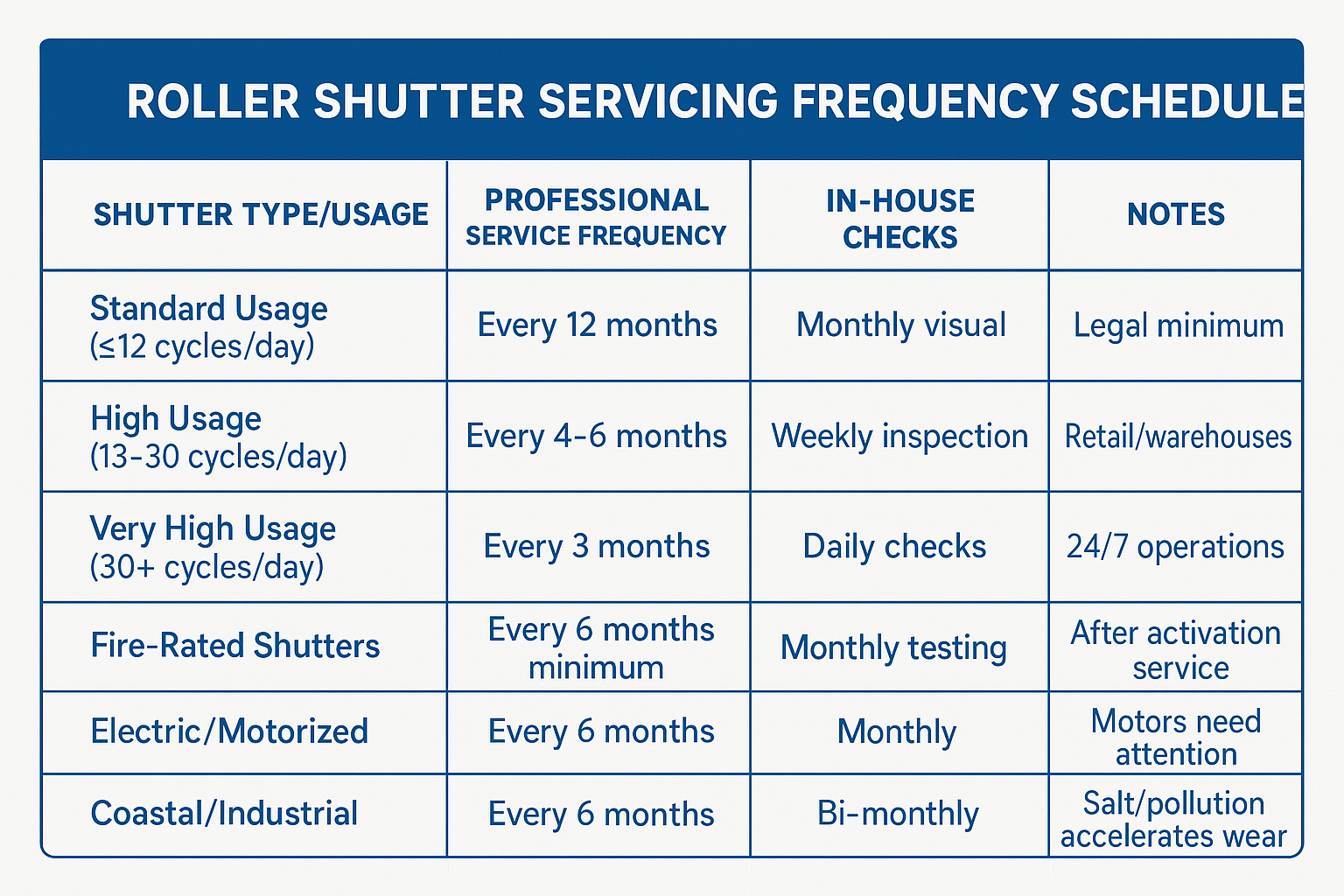

The frequency of professional servicing depends primarily on how much you use your shutters and the environment they operate in. Getting this wrong doesn’t just risk equipment failure—it puts you in breach of legal requirements.

Standard commercial use, defined as up to 12 opening and closing cycles per day, requires annual professional servicing. This covers most office buildings, warehouses, and smaller retail operations that open once in the morning and close once at night.

High-use applications, involving 13-30 cycles daily, need servicing every four to six months. This includes busy retail premises, restaurants, and warehouses with frequent deliveries. Very high-use shutters, operating more than 30 cycles daily, require quarterly servicing to maintain reliability and compliance.

Electric and motorized shutters generally need more frequent attention than manual ones due to their additional mechanical and electrical components. The motors, control systems, and safety devices require regular testing and calibration to ensure proper operation.

Fire-rated shutters have the strictest requirements, mandating professional servicing every six months regardless of usage frequency. These shutters must also be inspected immediately after any fire alarm activation, even if they didn’t actually deploy.

Environmental factors also influence servicing frequency. Coastal locations require more frequent maintenance due to salt corrosion, while industrial environments with dust, chemicals, or vibration may need quarterly attention even for standard-use applications.

DIY Maintenance: What You Can Safely Do Yourself

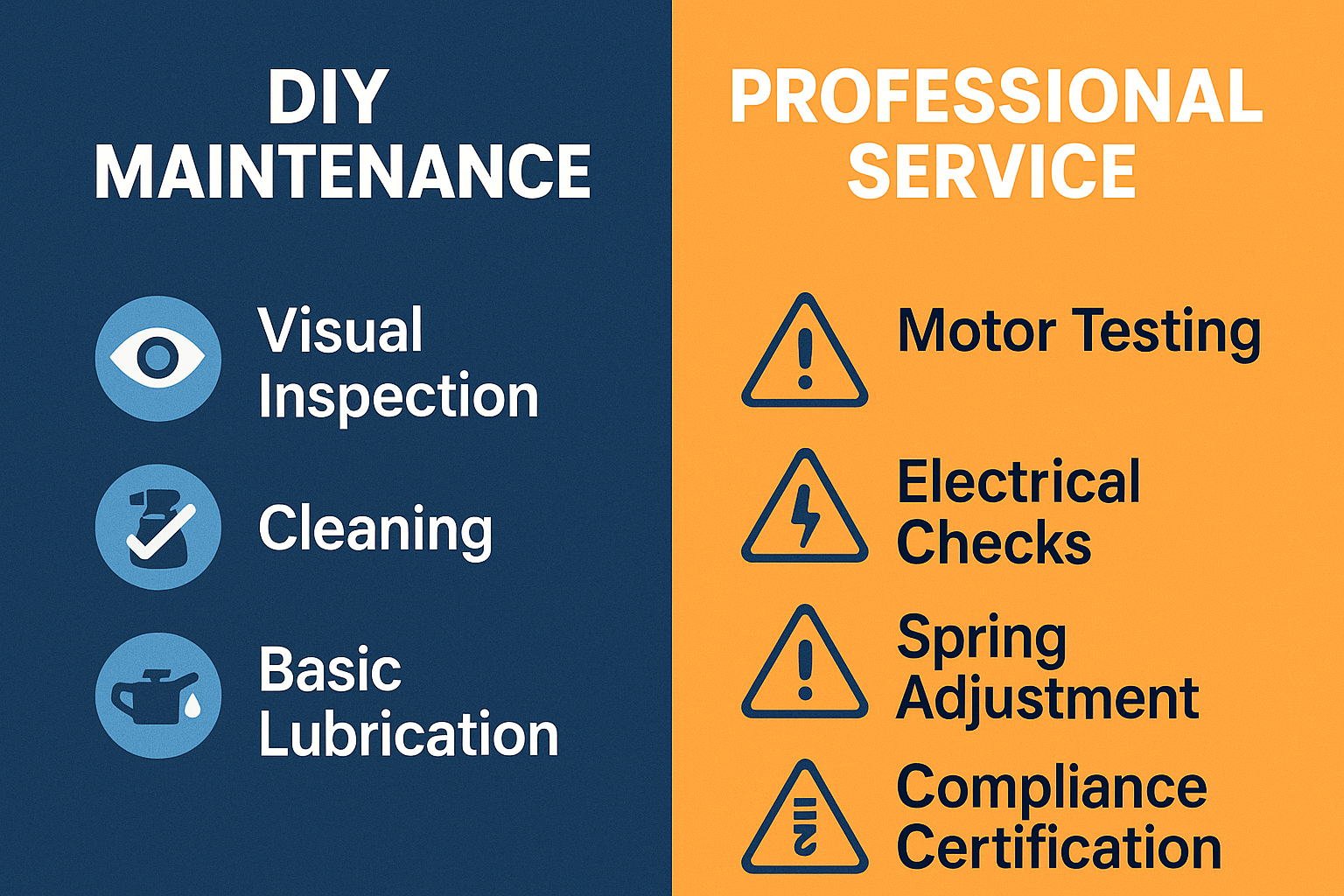

Between professional services, regular DIY maintenance helps keep your shutters running smoothly and can prevent many common problems. However, it’s crucial to understand the limits of what you can safely attempt.

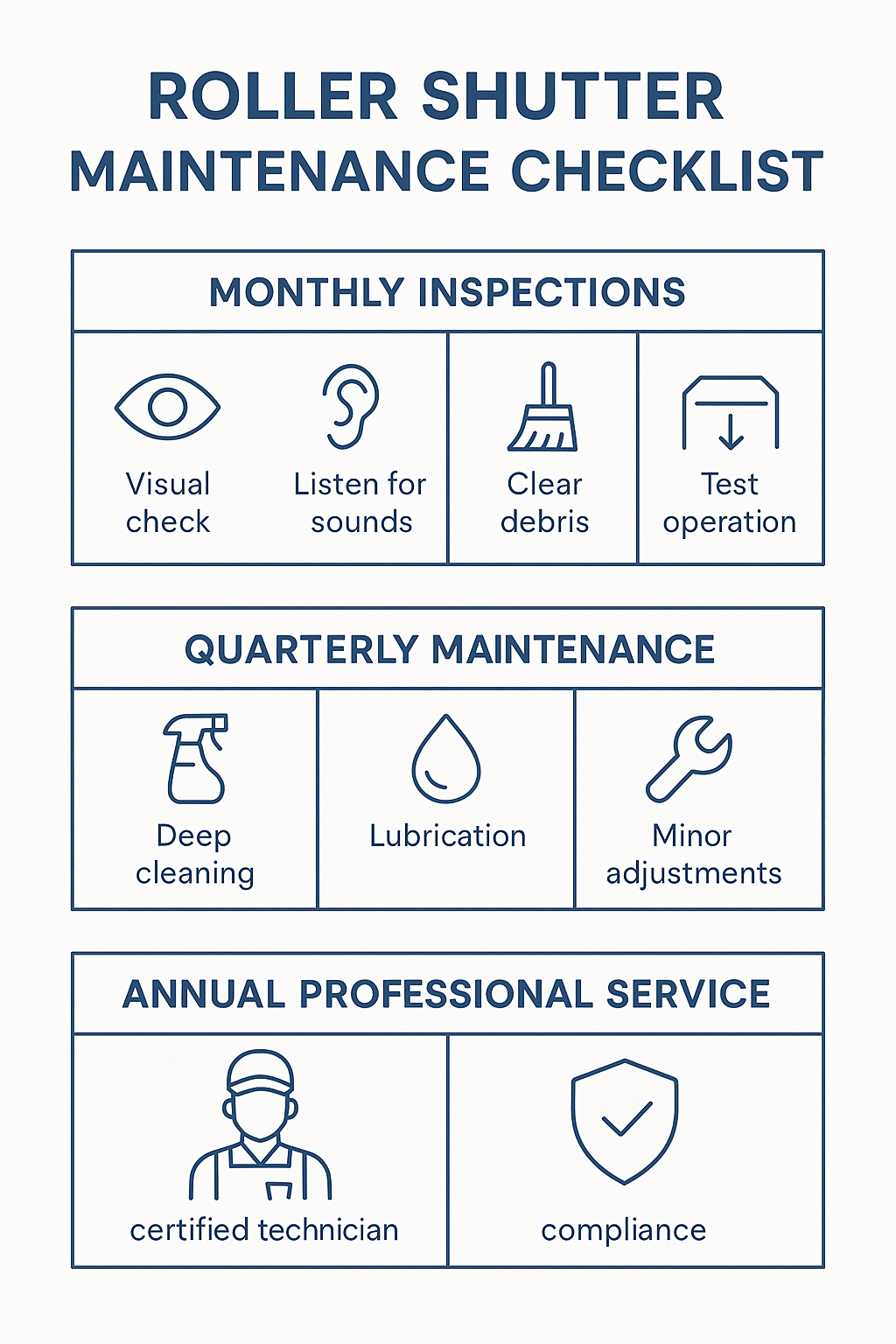

Monthly visual inspections form the foundation of good maintenance practice. During these checks, examine each slat for dents, cracks, or corrosion, and look for loose fixings or obvious damage. Operate the shutter slowly while listening for unusual noises, grinding sounds, or irregular movement patterns. Check that the shutter moves smoothly within its guides without binding or hesitation.

Quarterly cleaning prevents the buildup of dirt and debris that can cause operational problems. Start by clearing any obstructions from the tracks and guide channels, then clean the curtain with mild detergent and warm water. Avoid high-pressure washers or abrasive cleaners, which can damage seals and protective coatings. Pay particular attention to drainage points, ensuring they remain clear to prevent water accumulation.

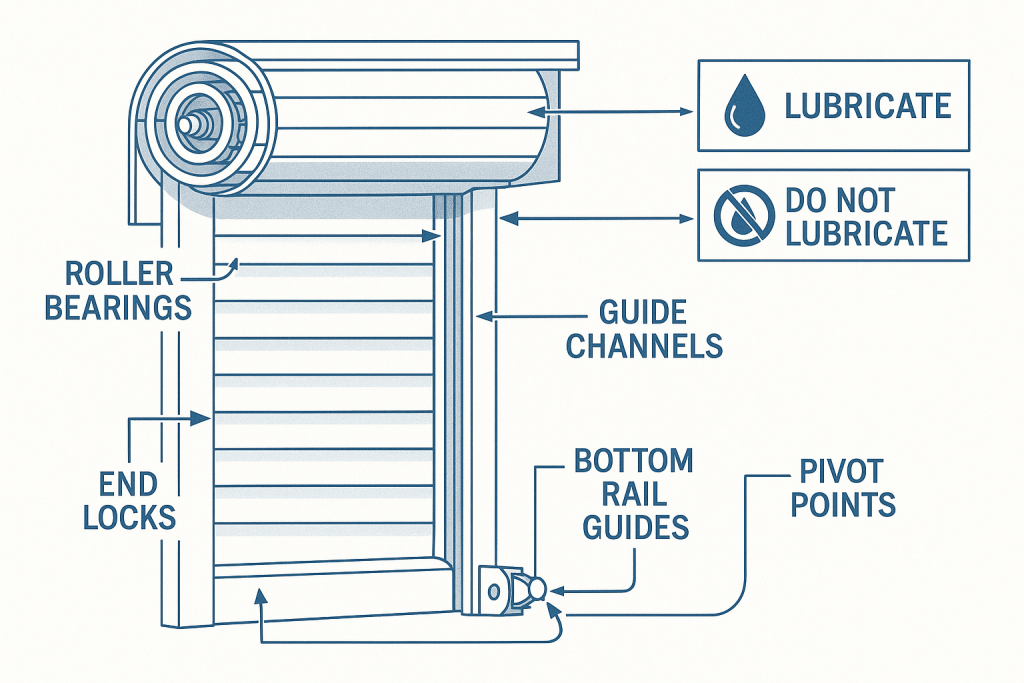

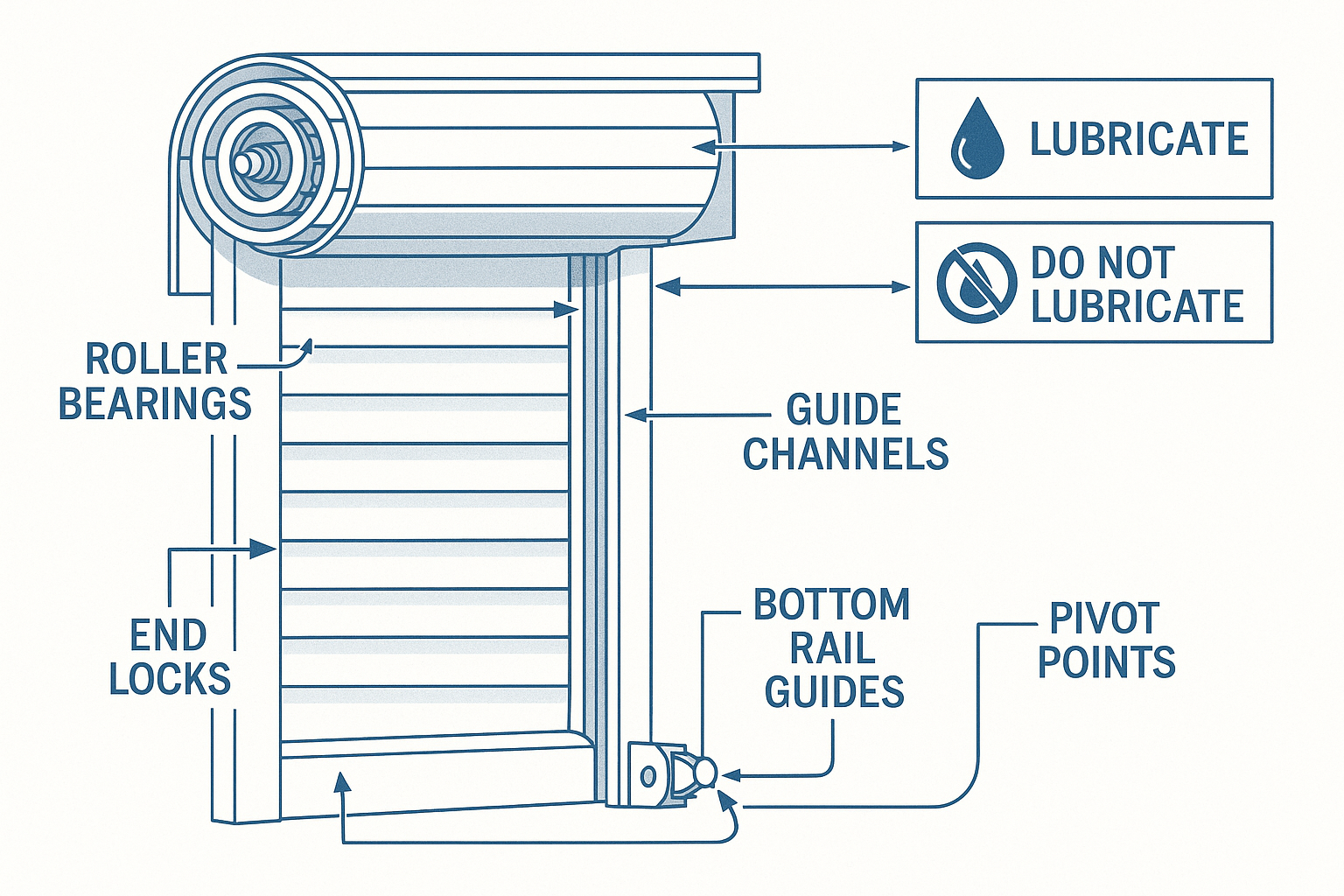

Bi-annual lubrication keeps moving parts operating smoothly and reduces wear. Use only silicone-based spray lubricants, applying them sparingly to roller bearings, guide channels, end locks, and pivot points. Never lubricate motor components, electrical connections, or brake mechanisms—these require professional attention.

The most important rule of DIY maintenance is knowing what not to attempt. Never try to adjust spring tension, repair motors, modify electrical connections, or bypass safety features. These tasks are extremely dangerous and must only be performed by qualified professionals. Spring-loaded components in particular can cause serious injury or death if handled incorrectly.

Warning Signs That Require Immediate Professional Attention

Recognizing the early warning signs of shutter problems can save you thousands in emergency repair costs and prevent dangerous situations. Some issues require immediate professional intervention, while others can wait for scheduled maintenance.

Emergency situations demand immediate professional response. If your shutter won’t open or close at all, you have a security emergency that needs same-day attention. Similarly, any grinding, scraping, or banging noises indicate potential mechanical failure that could worsen rapidly without intervention.

Electrical problems require particular caution. Burning smells from motors or control panels, exposed wiring, or sparking components represent serious safety hazards. Never attempt to use a shutter showing these symptoms—isolate the power supply and call for emergency repair immediately.

Operational problems like uneven movement, intermittent operation, or increased noise levels indicate developing issues that need professional assessment. While these may not require emergency response, they should be addressed promptly to prevent more serious failures.

Visual damage such as significant rust, bent slats, or misaligned components also warrants professional attention. While minor surface rust can be treated during routine maintenance, extensive corrosion or structural damage requires immediate assessment to ensure safety and security.

Professional Servicing: What to Expect

Professional servicing goes far beyond basic DIY maintenance, providing comprehensive inspection, testing, and certification that ensures legal compliance and optimal performance. Understanding what’s included helps you choose the right service provider and ensures you receive proper value.

A comprehensive professional service begins with detailed visual and operational inspection of all components. The technician will examine the curtain, guides, mounting points, and housing for signs of wear, damage, or misalignment. For electric shutters, this includes testing motor performance, checking electrical connections, and verifying safety system operation.

Deep cleaning and lubrication using professional-grade equipment and materials removes accumulated dirt and debris that can cause premature wear. Technicians use specialized lubricants appropriate for each component and environmental conditions, ensuring optimal performance without attracting contamination.

Mechanical adjustments include spring tension optimization, limit switch calibration, and alignment corrections. These precise adjustments require specialized knowledge and equipment, ensuring the shutter operates smoothly while maintaining proper safety margins.

Safety testing verifies that all protective systems function correctly. This includes testing auto-reverse mechanisms, emergency stop functions, and obstacle detection systems. For fire-rated shutters, additional testing ensures proper integration with fire alarm systems.

The service concludes with comprehensive documentation including photographic evidence of the shutter’s condition, detailed reports of work performed, and compliance certification. This documentation is essential for legal compliance and insurance purposes.

Seasonal Maintenance: Adapting to British Weather

The UK’s variable climate demands season-specific maintenance approaches to keep shutters performing reliably year-round. Each season brings particular challenges that require targeted attention.

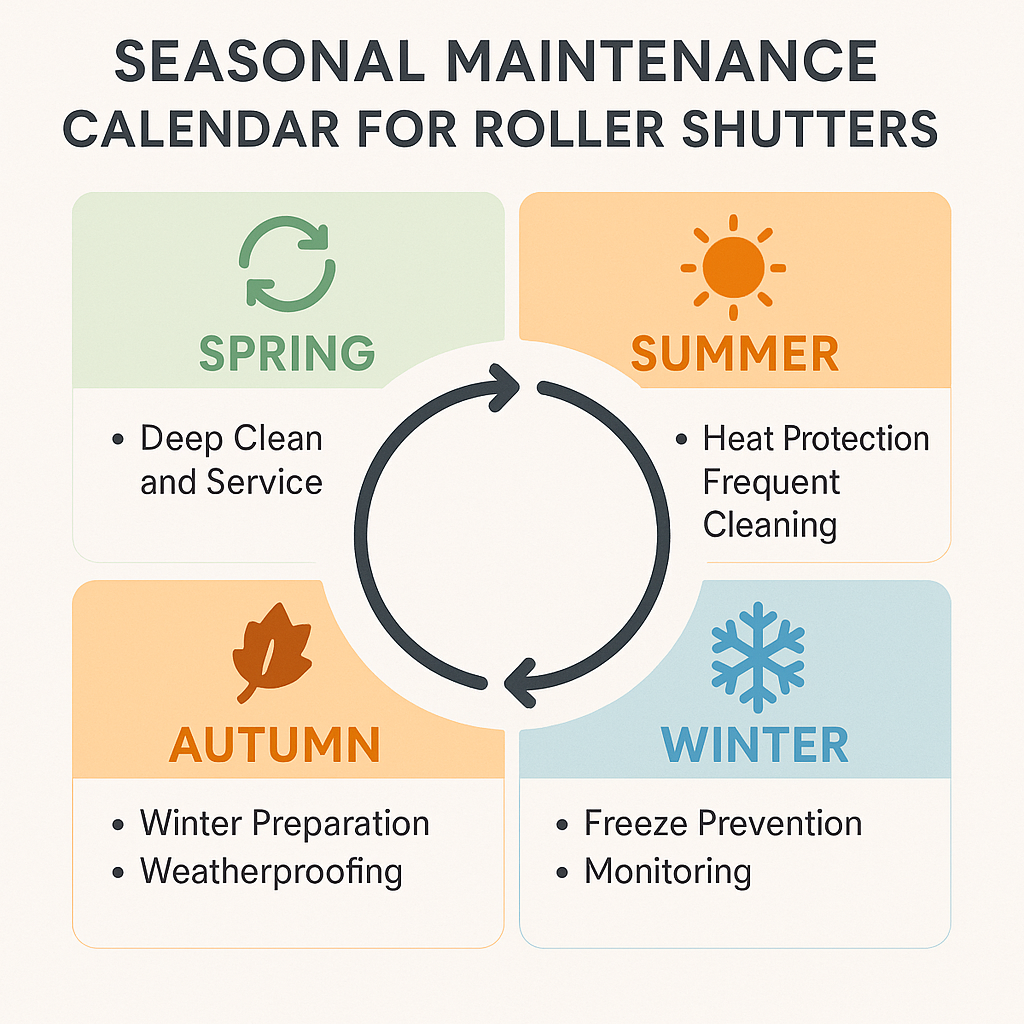

Spring preparation focuses on recovery from winter conditions. The combination of salt, moisture, and temperature fluctuations takes its toll on roller shutters, making spring the ideal time for comprehensive cleaning and professional servicing. Remove winter grime and salt deposits, treat any rust spots that have developed, and refresh lubrication that may have been washed away or contaminated.

Summer vigilance addresses heat-related challenges. High temperatures can cause thermal expansion that affects shutter alignment, while intense UV radiation can degrade protective coatings. Increase cleaning frequency to manage dust and pollen buildup, and monitor electrical components for overheating in control panels and motor housings.

Autumn preparation focuses on readiness for winter conditions. This is the time to ensure weather seals are in good condition, drainage systems are clear, and protective treatments are applied. If you haven’t had professional servicing in spring, autumn is the second-best time to ensure your shutters can withstand winter conditions.

Winter management emphasizes freeze prevention and careful operation. Never force frozen shutters to operate, as this can cause catastrophic damage. Instead, allow natural thawing or use gentle warming methods. Operate shutters more frequently during cold periods to prevent ice formation, and clear snow immediately to prevent accumulation and ice formation.

Common Problems and When to Call for Help

Understanding common roller shutter problems helps you identify issues early and determine whether you need immediate professional help or can wait for scheduled maintenance. Quick recognition and appropriate response can prevent minor issues from becoming major failures.

Operational problems are often the first sign of developing issues. If your shutter becomes slower to operate, makes new noises, or occasionally fails to respond to controls, these typically indicate mechanical wear or electrical problems that need professional assessment. While not usually emergencies, addressing these issues promptly prevents more serious failures.

Mechanical wear manifests as increased noise, rough operation, or visible damage to components. Minor surface rust can be treated during routine maintenance, but extensive corrosion or structural damage requires immediate professional attention. Similarly, damaged slats or misaligned guides need prompt repair to prevent further deterioration.

Electrical issues in motorized shutters require particular caution. Intermittent operation, error codes, or control problems often indicate developing faults that can worsen rapidly. Never attempt electrical repairs yourself—these require qualified technicians with appropriate testing equipment and safety knowledge.

For detailed information about specific problems and their solutions, our comprehensive guide on roller shutter repairs and common problems provides expert insights into troubleshooting and repair options.

Choosing the Right Maintenance Provider

Selecting a qualified maintenance provider is crucial for ensuring legal compliance, equipment reliability, and value for money. The cheapest option is rarely the best when it comes to critical security equipment.

Qualifications and experience should be your primary considerations. Look for technicians with formal training in roller shutter systems, understanding of relevant regulations, and experience with your specific type of equipment. They should carry appropriate insurance and be able to provide compliance certification.

Service scope varies significantly between providers. Ensure your chosen company offers comprehensive servicing including mechanical, electrical, and safety system testing. They should provide detailed reports with photographic evidence and clear recommendations for any additional work required.

Response times matter, particularly for emergency situations. Choose a provider offering reasonable emergency response times for your area, with clear pricing for out-of-hours calls. Regular service scheduling should be flexible enough to accommodate your business needs without disrupting operations.

Documentation and compliance support is essential for meeting legal requirements. Your service provider should maintain comprehensive records, provide compliance certificates, and offer guidance on regulatory requirements and best practices.

Conclusion: Protecting Your Investment and Your Business

Proper roller shutter maintenance isn’t just about keeping doors working—it’s about protecting your business, ensuring legal compliance, and avoiding costly emergencies. The small investment in regular maintenance pays dividends in reliability, security, and peace of mind.

The legal requirements are clear and non-negotiable. Annual professional servicing is the minimum requirement, with more frequent attention needed for high-use applications. Proper documentation is essential for compliance and insurance purposes.

DIY maintenance between professional services helps maintain performance and identify developing problems early. However, understanding the limits of what you can safely attempt is crucial for avoiding dangerous situations and potential equipment damage.

Your next steps are straightforward: assess when your shutters were last professionally serviced, implement regular DIY inspections and cleaning, and establish a relationship with a qualified service provider for ongoing maintenance and emergency support.

Don’t wait for a breakdown to think about maintenance. Every day you delay increases your risk of costly emergency repairs, security breaches, and legal non-compliance.

Ready to Protect Your Investment?

Huxley & Co – Professional Roller Shutter Specialists

With over 20 years of experience serving businesses across the UK, we understand the critical role roller shutters play in your operations. Our qualified technicians provide comprehensive maintenance services that keep you compliant, secure, and operational.

📞 Call: 0207 112 4849 (24/7 Emergency Line)

📧 Email: info@huxleyandco.co.uk

🌐 Online: Book Your Free Assessment

Service Areas: London, Essex, Kent, Surrey, Hertfordshire, and surrounding areas

Trusted by leading brands including KFC, Boots, Nando’s, and APM Monaco

Related Articles:

- Roller Shutter Repairs: Most Common Roller Shutter Problems

- Cost of Shutters: Complete Guide

- What Are the Benefits of Brand New Roller Shutters?

This guide is updated regularly to reflect current UK regulations and industry best practices. For specific advice about your roller shutters, contact Huxley & Co for a professional assessment.