Toughened Glass vs Tempered Glass: What’s the Difference?

Table of Contents

Table of Contents

- Toughened Glass vs Tempered Glass: What’s the Difference?

- Toughened Glass vs Tempered Glass: The Truth

- What Is Toughened Glass? Complete Explanation

- British Standards and UK Regulations

- Applications and Thickness Guide

- Toughened vs Laminated Glass: Key Differences

- Cost Guide: Toughened Glass Prices UK

- Advantages and Limitations

- Frequently Asked Questions

- Professional Installation and Service

- Get Professional Toughened Glass Installation

If you’ve been researching glass specifications for your commercial property or shop front, you’ve likely encountered both terms: toughened glass and tempered glass. You might be wondering what the difference is between these two types of safety glazing, which one you should specify, and whether one is superior to the other for your project.

Here’s the straightforward answer that will save you considerable time and confusion: toughened glass and tempered glass are exactly the same product. There is no difference whatsoever in their manufacturing process, physical properties, performance characteristics, or safety features. These are simply two different names for the identical type of heat-treated safety glass.

In the UK and throughout Europe, we predominantly use the term “toughened glass.” In the United States and some other regions, the same product is called “tempered glass.” Both terms refer to glass that has been thermally treated through a process of extreme heating and rapid cooling to increase its strength and change its breakage characteristics.

In our 20+ years installing commercial glazing across London, Essex, Kent, Surrey, and Hertfordshire, we’ve worked with major retailers including KFC, Boots, Nando’s, and APM Monaco. We’ve specified and fitted thousands of square metres of toughened glass, and this terminology confusion comes up regularly with clients, architects, and property managers.

This comprehensive guide will clarify the naming conventions, explain exactly what toughened glass is, detail the UK regulations that govern its use, outline the manufacturing process, and help you understand where and why this safety glazing is required for your commercial or residential property. Whether you’re fitting out a new shop front, replacing glazing in an office building, or simply want to understand British Standards compliance, this guide provides everything you need to know.

GET A FREE GLAZING QUOTE | EMERGENCY GLAZING: 0207 112 4849

Toughened Glass vs Tempered Glass: The Truth

Let’s address this confusion definitively: toughened glass and tempered glass are the same thing. When you see these terms used interchangeably in specifications, datasheets, or supplier catalogues, they’re referring to an identical product manufactured through the same thermal treatment process.

Why Do Two Names Exist?

The terminology difference is purely regional and linguistic. In British English, we say “toughened glass.” In American English, the term is “tempered glass.” Neither term is more correct than the other—they’re simply regional preferences that have become standardized within their respective markets.

This is similar to how we might say “lift” in the UK while Americans say “elevator,” or how we refer to “pavements” where Americans say “sidewalks.” The object itself hasn’t changed; only the word we use to describe it differs.

Where Did These Terms Originate?

The thermal treatment process for strengthening glass was developed in the early 20th century. As the technology spread globally, different English-speaking regions adopted different terminology. The British and European glass industry gravitated toward “toughened”—emphasizing the material’s enhanced toughness and durability. The American glass industry adopted “tempered”—referencing the tempering process used in metallurgy, where heating and rapid cooling strengthen materials.

Both terms are technically accurate. The glass is indeed toughened (made tougher than standard glass), and it’s also tempered (heat-treated through a tempering process).

Industry Standards Use Both Terms

If you examine international glass standards, you’ll notice both terms appearing depending on the document’s origin:

| Region | Preferred Term | Standard Example |

|---|---|---|

| UK & Europe | Toughened Glass | BS EN 12150 (Thermally toughened soda lime silicate safety glass) |

| United States | Tempered Glass | ASTM C1048 (Heat-Treated Flat Glass) |

| International | Both Used | ISO standards reference both terms |

| Australia | Toughened Glass | AS/NZS 2208 (Safety glazing materials) |

When British Standard BS EN 12150 refers to “thermally toughened soda lime silicate safety glass,” it’s describing the same product that American Standard ASTM C1048 calls “heat-strengthened and fully tempered glass.”

What This Means for Your Project

When you’re reviewing specifications, supplier quotes, or building regulations documents, you can treat “toughened” and “tempered” as completely interchangeable terms. If an American manufacturer supplies “tempered glass,” it will meet UK requirements for toughened glass, provided it complies with the relevant British Standard (BS EN 12150).

Similarly, if you’re sourcing glass internationally, don’t be concerned when suppliers use different terminology. Focus instead on ensuring the glass meets the required British Standards for your application, has the correct certification markings, and includes appropriate documentation.

In our commercial installations, we consistently use “toughened glass” when communicating with UK clients, architects, and building control officers, as this is the recognized terminology in British regulations and standards. However, when sourcing from international suppliers or reviewing technical literature from global manufacturers, we recognize that “tempered glass” refers to the identical product.

What Is Toughened Glass? Complete Explanation

Toughened glass (or tempered glass, as we’ve established) is safety glazing that has been thermally treated to dramatically increase its strength and alter the way it breaks. The process creates a glass panel approximately four to five times stronger than ordinary annealed glass of the same thickness, whilst simultaneously engineering a safer breakage pattern.

The Fundamental Properties

When you handle a piece of toughened glass, it looks identical to standard glass. The transparency is the same, the weight is virtually identical, and to the untrained eye, nothing appears different. However, the molecular structure has been fundamentally altered through thermal treatment, creating three distinct characteristics:

Enhanced Strength: Toughened glass can withstand significantly greater impact force and pressure than annealed glass. Where a 6mm annealed glass panel might fracture under relatively modest impact, a 6mm toughened panel can absorb four to five times that force before breaking.

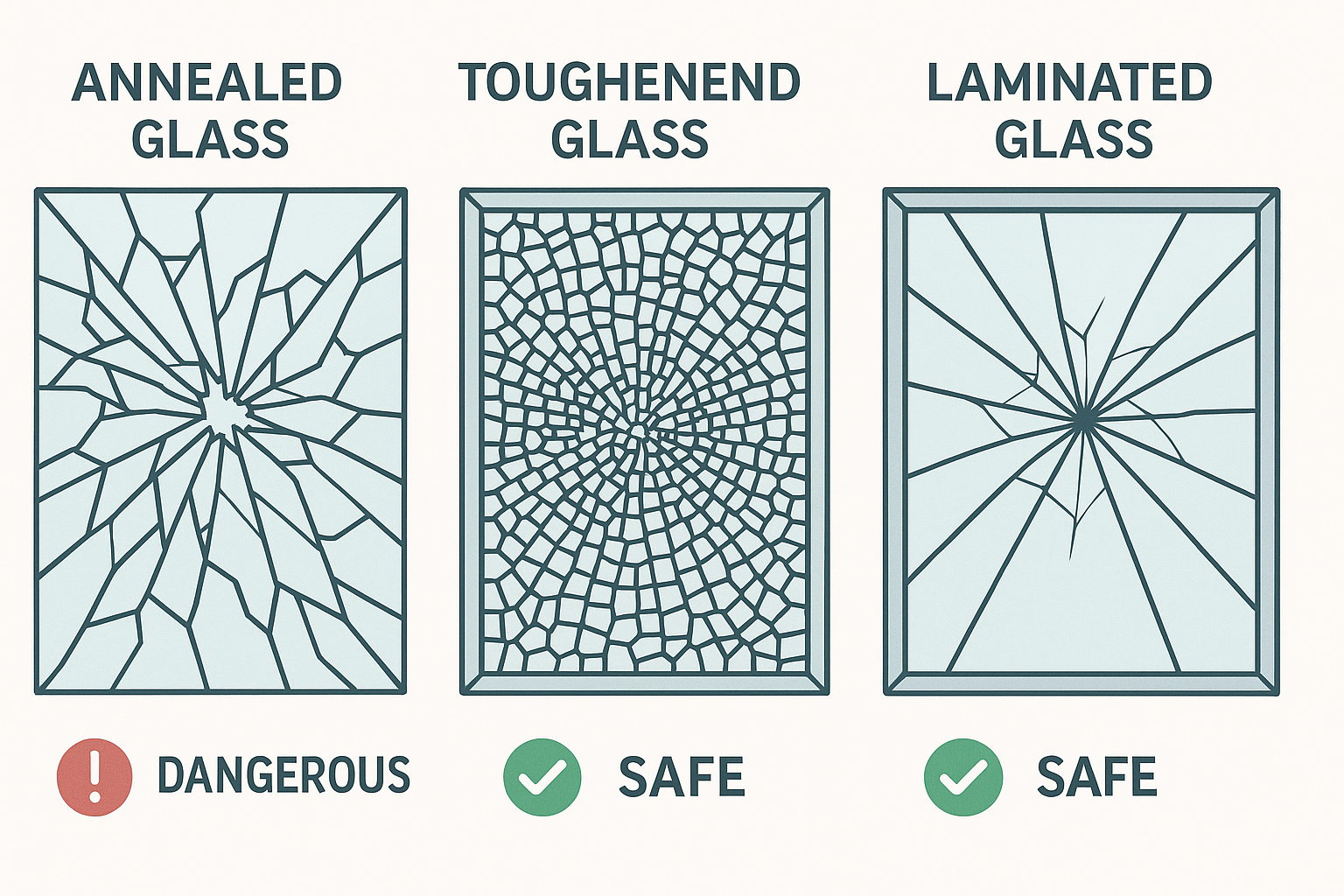

Altered Breakage Pattern: Perhaps the most critical safety feature is how toughened glass breaks. Rather than shattering into large, sharp, dagger-like shards (as annealed glass does), toughened glass disintegrates into thousands of small, relatively blunt, dice-like pieces. These fragments are far less likely to cause serious lacerations or injuries.

Thermal Stress Resistance: The tempering process creates a glass panel that can withstand greater temperature differentials without cracking. This makes toughened glass suitable for applications involving heat exposure or rapid temperature changes.

How Toughened Glass Differs from Annealed Glass

To understand what makes toughened glass special, it’s helpful to understand annealed glass—the standard glass product before any strengthening treatment.

Annealed glass is produced through the float glass process, where molten glass is floated over molten tin to create a perfectly flat surface. After forming, the glass ribbon is cooled slowly and evenly in a controlled annealing process. This creates glass with uniform internal stress distribution.

The problem with annealed glass is twofold: it’s relatively fragile, and when it breaks, it creates long, pointed shards that cause serious injuries. These characteristics make annealed glass unsuitable for many commercial applications and illegal in certain locations under UK Building Regulations.

Toughened glass addresses both issues. The tempering process locks the glass into a state of permanent stress—the surfaces are under compression whilst the interior is under tension. This compression layer on both surfaces must be overcome before the glass can break, which is why significantly greater force is required.

When toughened glass finally does break, the internal tension causes it to shatter completely and immediately into thousands of small pieces. There’s no opportunity for large shards to form because the entire panel fractures simultaneously across its entire area.

The Manufacturing Process in Detail

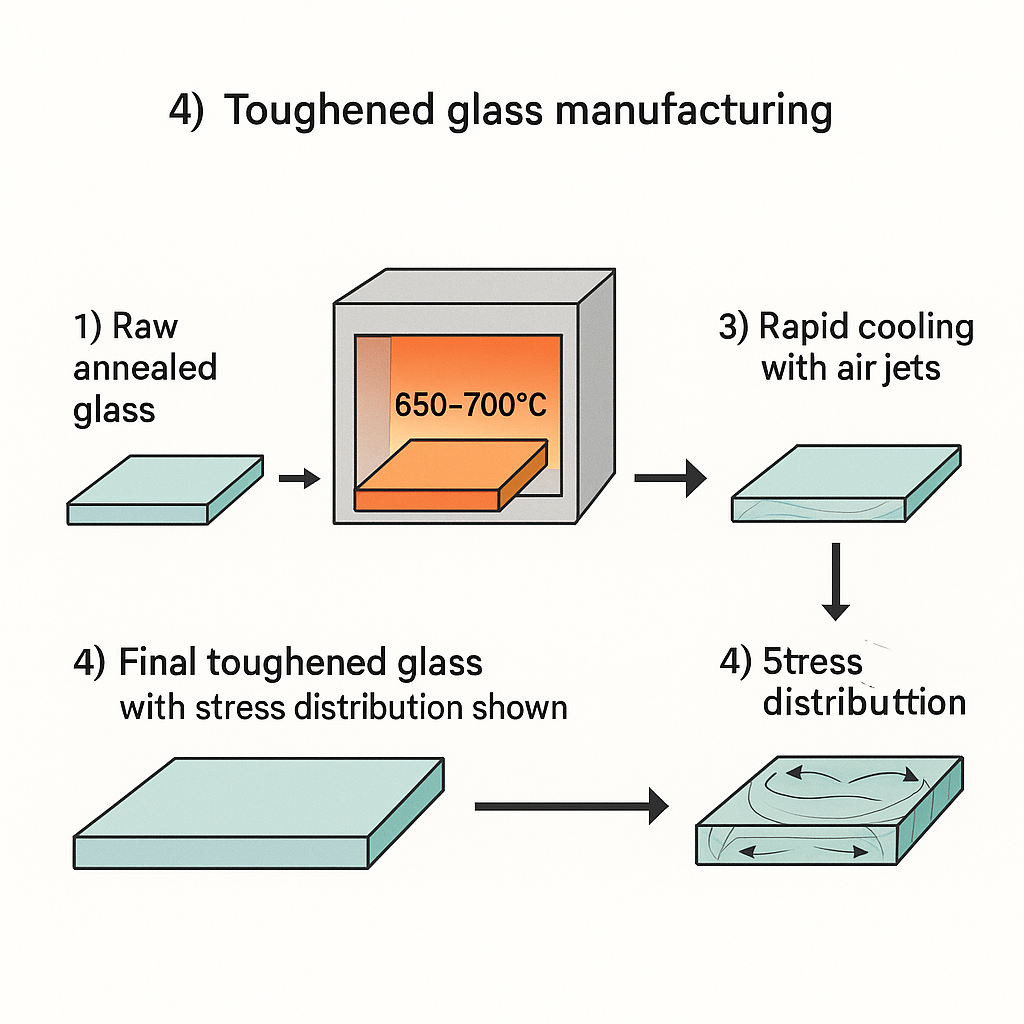

Toughened glass begins as standard annealed glass that’s cut to size and finished before thermal treatment. The glass is then heated in a tempering furnace to approximately 650-700°C—well above the glass transition temperature of roughly 564°C.

At this temperature, the glass becomes pliable. It’s then subjected to rapid, forced air cooling (quenching) directed at both surfaces simultaneously. This rapid cooling causes the surfaces to solidify and “set” whilst the interior remains temporarily molten.

As the interior subsequently cools more slowly, it tries to contract, but the already-solid surfaces constrain this contraction. The result is permanent compressive stress on the surfaces (typically 69-100 MPa or higher) and permanent tensile stress in the interior.

This stress distribution is what gives toughened glass its strength and characteristic breakage pattern. The surface compression must be overcome before the glass can fracture, and once the surface is breached, the internal tension causes complete, immediate shattering.

Why Toughened Glass Cannot Be Cut or Altered

One critical limitation of toughened glass is that it cannot be cut, drilled, or edge-worked after the tempering process. Any attempt to do so disrupts the carefully balanced stress distribution, causing the entire panel to shatter instantly.

We’ve seen this happen on sites where well-meaning contractors attempted to “just take a few millimetres off” a toughened glass panel that didn’t quite fit. The moment the cutting wheel touches the edge, the entire panel explodes into thousands of pieces.

This means all sizing, cutting, holes, notches, edge finishing, and any other fabrication must be completed before the glass enters the tempering furnace. This requirement demands precise measurement and planning—there’s no opportunity for on-site adjustments.

Identifying Toughened Glass

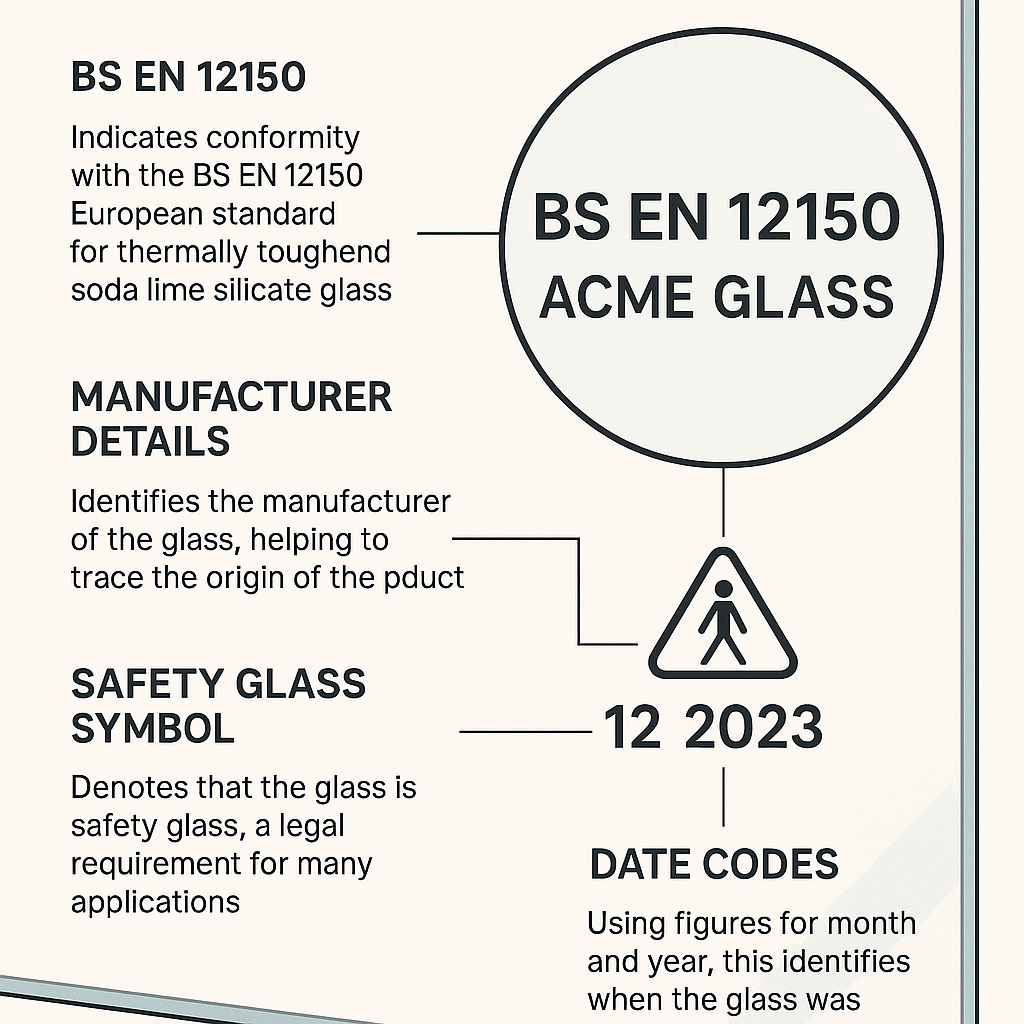

Toughened glass panels must carry permanent markings identifying them as safety glass and showing compliance with relevant standards. In the UK, you’ll typically see:

- British Standard marking (BS EN 12150)

- Manufacturer identification

- Safety glass symbol

- Toughening date or batch code

These markings are usually etched or printed in one corner of the panel and remain permanently visible. If you’re unsure whether existing glazing is toughened, look for these markings. Standard annealed glass won’t carry them.

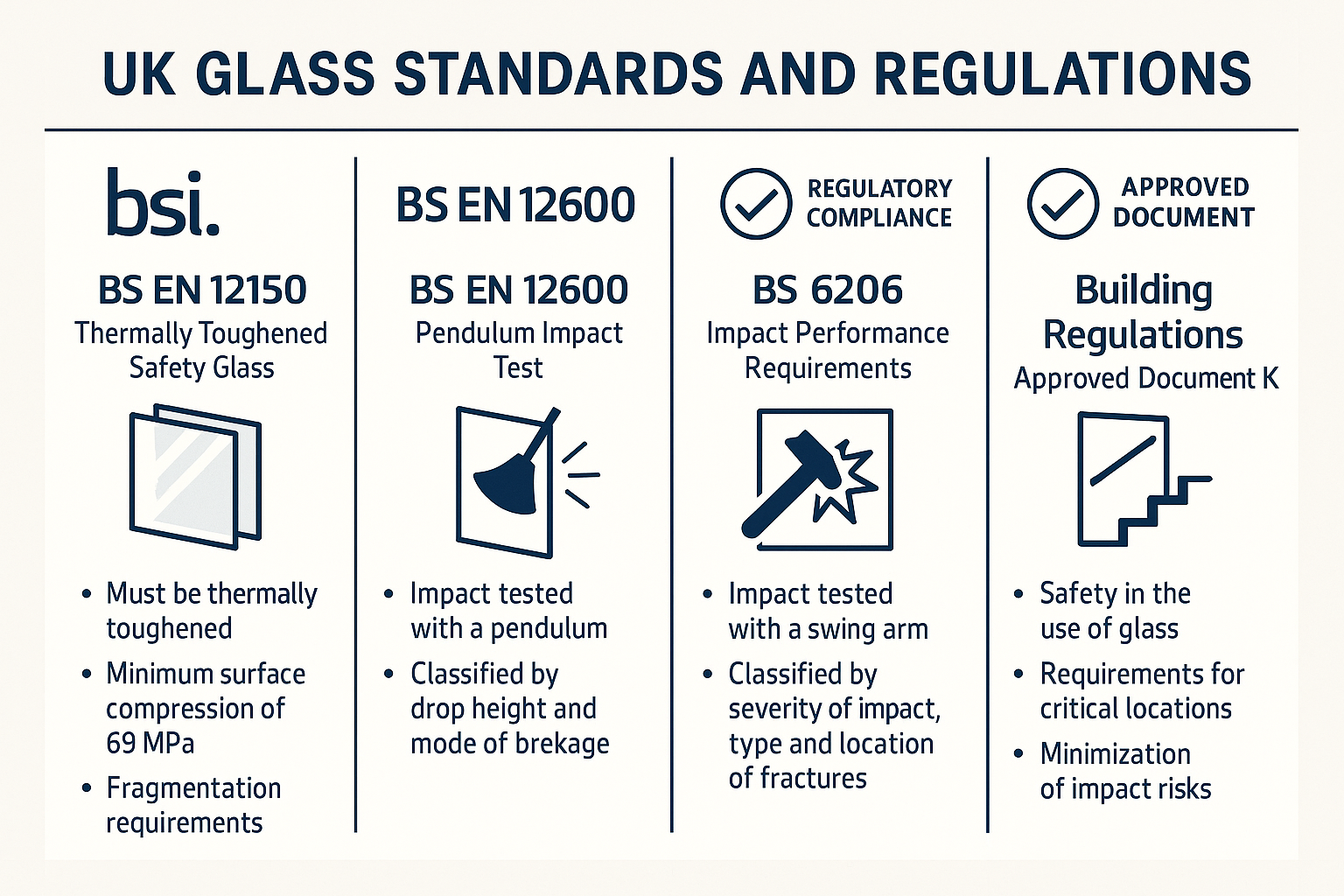

British Standards and UK Regulations

Understanding UK regulations governing toughened glass is essential for compliance, safety, and avoiding potentially costly mistakes. Building Control officers take glazing safety seriously, and non-compliant installations may require expensive replacement before buildings can be occupied or receive completion certificates.

BS EN 12150: The Primary Standard

The fundamental British Standard for toughened glass is BS EN 12150-1: Glass in building – Thermally toughened soda lime silicate safety glass – Part 1: Definition and description. This European standard, adopted in the UK, defines the requirements for what constitutes thermally toughened safety glass.

BS EN 12150 specifies the minimum surface compression (69 MPa), fragment characteristics upon breakage, and manufacturing requirements. Any toughened glass supplied for building applications in the UK should comply with and be marked according to this standard.

The standard covers:

- Minimum surface compression stress requirements

- Fragment characteristics (approximately 40-200 pieces in a 50mm x 50mm area)

- Dimensional tolerances

- Edge working requirements

- Permanent marking requirements

BS EN 12600: Impact Testing

BS EN 12600: Glass in building – Pendulum test – Impact test method and classification for flat glass establishes how safety glass is tested for impact resistance and how products are classified based on performance.

This standard uses a pendulum test with twin tyres to simulate human impact. Glass is classified according to:

- Drop height withstood (1200mm, 450mm, or 190mm)

- Mode of breakage (A, B, or C)

- Fragmentation characteristics

Toughened glass typically achieves Class 1B1 or 2B2 classification, meaning it withstands the highest impact energies whilst breaking safely.

UK Building Regulations: Approved Document K

Approved Document K: Protection from falling, collision and impact contains the regulations that actually mandate where safety glazing must be used in buildings.

Critical locations requiring safety glazing include:

Doors and Door Side Panels: Any glazing in doors and within 300mm either side of a door edge must be safety glass if located between finished floor level and 1500mm above that level.

Large Glazed Areas: Glazing below 800mm from floor level in areas where people might collide with it must be safety glass unless the risk is minimal (such as glass protected by barriers).

Bath and Shower Glazing: All glazing used in bath or shower screens, enclosures, or adjacent to baths and showers must be safety glazing.

Stairs, Ramps, and Landings: Glazing on or adjacent to these areas requires safety glazing to protect against impact.

Manifestation Requirements: Large glazed areas must include manifestation (visible markings) to prevent people walking into them, or use safety glazing throughout.

Commercial Applications and Compliance

For commercial premises, additional considerations apply beyond basic Building Regulations:

Shop Fronts: While not always legally mandated, toughened glass is standard practice for shop fronts due to security concerns, impact resistance, and insurance requirements.

Fire Safety: Fire-rated glazing must maintain its integrity during fire conditions. Toughened glass can be incorporated into fire-rated assemblies, but the complete system must be tested and certified.

Accessibility: The Equality Act 2010 requires consideration of accessibility in commercial premises. Manifestation on large glazed areas helps visually impaired people identify glass barriers.

Insurance Requirements: Many commercial insurance policies require or incentivize safety glazing in vulnerable locations. Check your policy terms before specifying glazing.

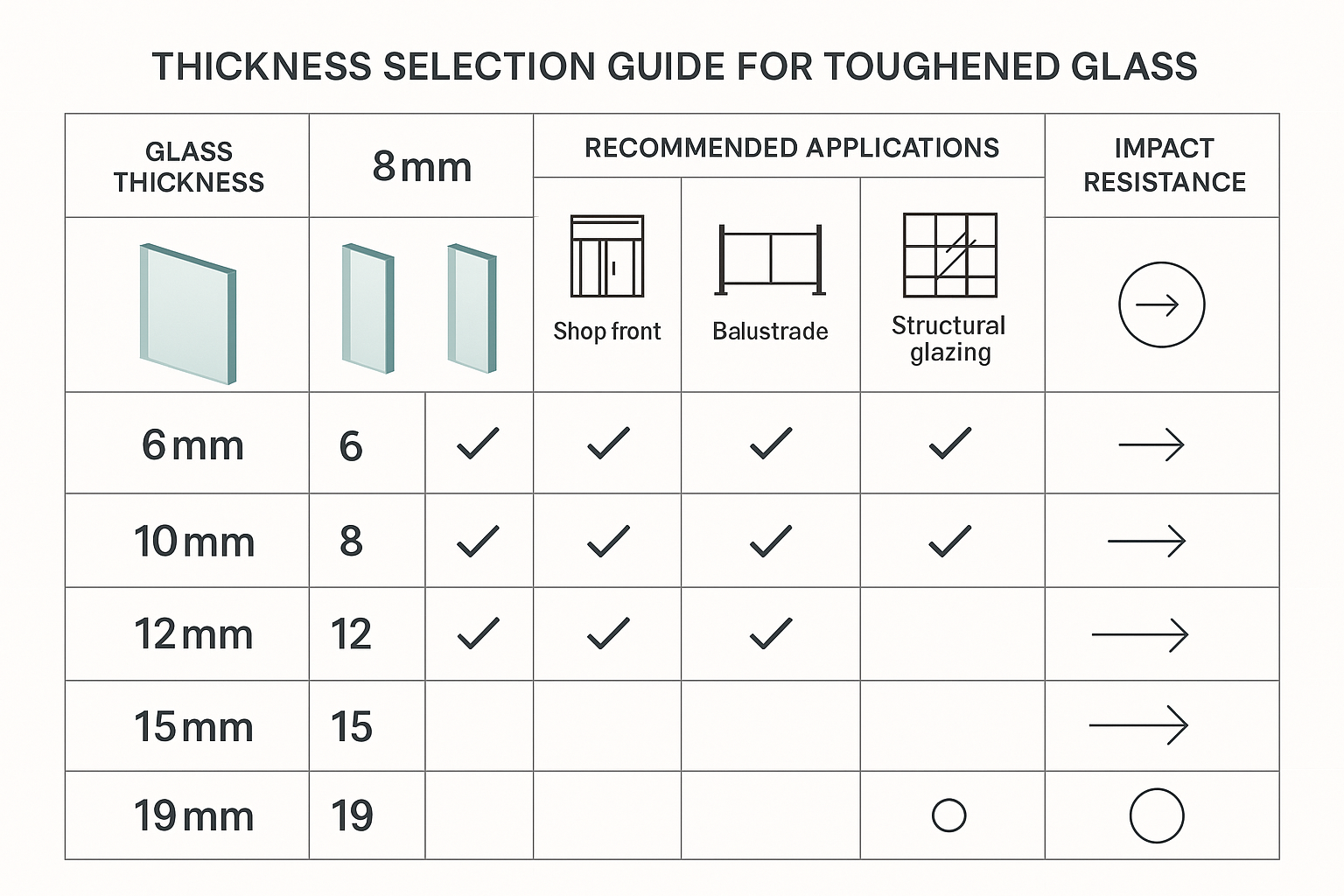

Applications and Thickness Guide

Selecting the appropriate thickness and specification of toughened glass depends on your specific application, wind loading, security requirements, and budget considerations.

Residential Applications

Shower Screens and Bathroom Glazing: Typically 6mm or 8mm toughened glass provides adequate strength for residential shower enclosures. The thickness choice depends on panel size and design—larger panels or frameless designs may require 8mm for stability.

Patio and Bifold Doors: Residential doors commonly use 6mm toughened glass in double-glazed units. For larger panels or exposed locations, 8mm provides additional security and wind resistance.

Internal Doors and Partitions: 6mm toughened glass is standard for internal applications where safety glazing is required. The reduced thickness keeps weight manageable whilst meeting safety requirements.

Garden Buildings: Greenhouses, conservatories, and garden rooms benefit from toughened glass for safety and thermal performance. 4mm toughened glass is often adequate for smaller panels, whilst 6mm suits larger installations.

Commercial Applications

Shop Fronts: Commercial glazing typically starts at 10mm thickness for adequate security and wind resistance. High-street retail often specifies 12mm or 15mm for enhanced security against break-in attempts.

Office Partitions: 8mm or 10mm toughened glass provides the right balance of safety, acoustic performance, and cost for most office environments. Larger panels may require 12mm for stability.

Entrance Doors: Commercial entrance doors commonly use 10mm or 12mm toughened glass to withstand heavy use and provide security. Automatic doors may require specific thicknesses for proper operation.

Balustrades: Glass balustrades require structural calculations, but typically use 12mm, 15mm, or 17.5mm toughened glass depending on height, wind loading, and safety factors.

Structural and Specialist Applications

Overhead Glazing: Roof lights, canopies, and overhead glazing require laminated glass for safety, but the individual panes are often toughened for strength. Typical specifications range from 6mm to 12mm per pane.

High-Rise Glazing: External glazing on tall buildings faces extreme wind loads and thermal stress. Specifications typically start at 12mm and may exceed 19mm for the most demanding applications.

Security Glazing: High-security applications combine toughened glass with laminated construction. Multiple layers of toughened glass with security interlayers provide both strength and attack resistance.

Specialist Applications: Swimming pool glazing, marine applications, and industrial environments may require custom specifications based on specific environmental conditions and performance requirements.

Wind Loading Considerations

Glass thickness selection must account for wind loading, which varies by location, building height, and exposure. A structural engineer should calculate wind loads for critical applications, but general guidance includes:

Ground Level, Sheltered: Standard thicknesses often adequate

Ground Level, Exposed: Increase thickness by one step (e.g., 10mm instead of 8mm)

Upper Floors: Significant thickness increases may be required

Coastal or Hilltop Locations: Enhanced specifications essential

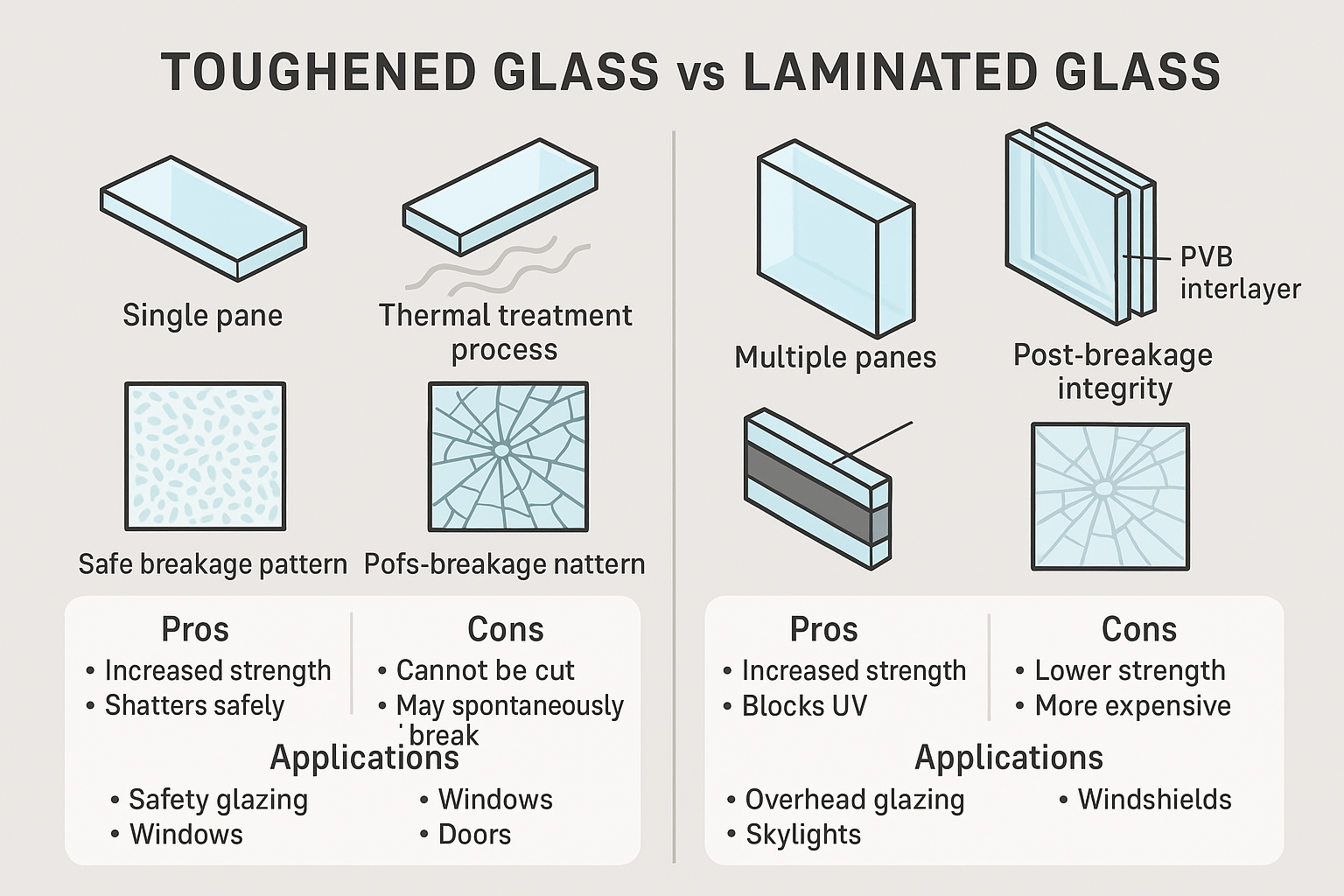

Toughened vs Laminated Glass: Key Differences

Understanding the difference between toughened and laminated glass is essential for specifying appropriate glazing. These are fundamentally different products with different manufacturing processes, characteristics, and optimal applications.

Manufacturing Process Comparison

Toughened glass is a single piece of glass thermally treated through heating and rapid cooling to alter its internal stress distribution, as we’ve discussed extensively.

Laminated glass consists of two or more glass panes bonded together with a plastic interlayer—typically polyvinyl butyral (PVB). The glass panes themselves might be annealed or toughened. The laminated assembly is created through heat and pressure, bonding the glass to the interlayer.

The result is a composite material where the interlayer holds glass fragments in place if breakage occurs.

Breakage Behavior: The Critical Difference

The most significant difference between these safety glazing types is what happens when they break:

Toughened glass shatters completely into thousands of small dice-like pieces that fall away from the opening. This safe fragmentation minimizes injury risk, but it also means the opening is immediately unprotected—there’s no remaining barrier to weather, intrusion, or further access.

Laminated glass cracks but remains largely intact. The glass panes may fracture, but the fragments adhere to the plastic interlayer. The glazing continues to provide a barrier even after breaking, maintaining security and weather protection.

This difference dictates appropriate applications:

Use toughened glass when:

- Safe fragmentation is the primary concern

- Maintaining a barrier after breakage isn’t critical

- Cost efficiency is important

- Thermal stress resistance is required

Use laminated glass when:

- Security is paramount

- Post-breakage barrier function matters

- Overhead glazing requires fail-safe performance

- Acoustic insulation is required

- UV filtering is desired (PVB filters approximately 99% of UV)

Strength and Performance

Toughened glass is significantly stronger than annealed laminated glass. A single pane of toughened glass withstands greater impact than two panes of annealed glass laminated together.

However, toughened laminated glass—where the glass panes in the laminated assembly are themselves toughened—combines the strength of toughening with the post-breakage integrity of lamination. This premium specification provides the best of both characteristics.

For demanding applications like shop fronts in high-crime areas, glass balustrades, or overhead structural glazing, toughened laminated glass is often the optimal choice despite higher cost.

Security Properties

Laminated glass provides superior security against forced entry. An intruder breaking laminated glass faces a flexible membrane that resists penetration even when the glass fractures. Continued attack is required to create an opening, providing more time for alarms and response.

Toughened glass, once broken, provides no further resistance. For retail environments concerned about smash-and-grab theft or ram raids, laminated or toughened laminated glass offers better protection.

Security-rated glazing typically involves multiple laminated layers with upgraded interlayers designed specifically for attack resistance.

Cost Comparison

Toughened glass is generally less expensive than laminated glass of equivalent overall thickness, which is in turn less expensive than toughened laminated glass.

Approximate relative costs (actual prices vary with specification, quantity, and supplier):

- Toughened glass: Baseline cost

- Laminated glass (annealed): 1.3-1.5x toughened glass cost

- Toughened laminated glass: 1.6-2.0x toughened glass cost

- Heat-soaked toughened glass: 1.2-1.3x standard toughened glass cost

For large commercial projects, these cost differences become significant. A 100m² shop front might cost £8,000-10,000 in standard toughened glass or £13,000-18,000 in toughened laminated glass.

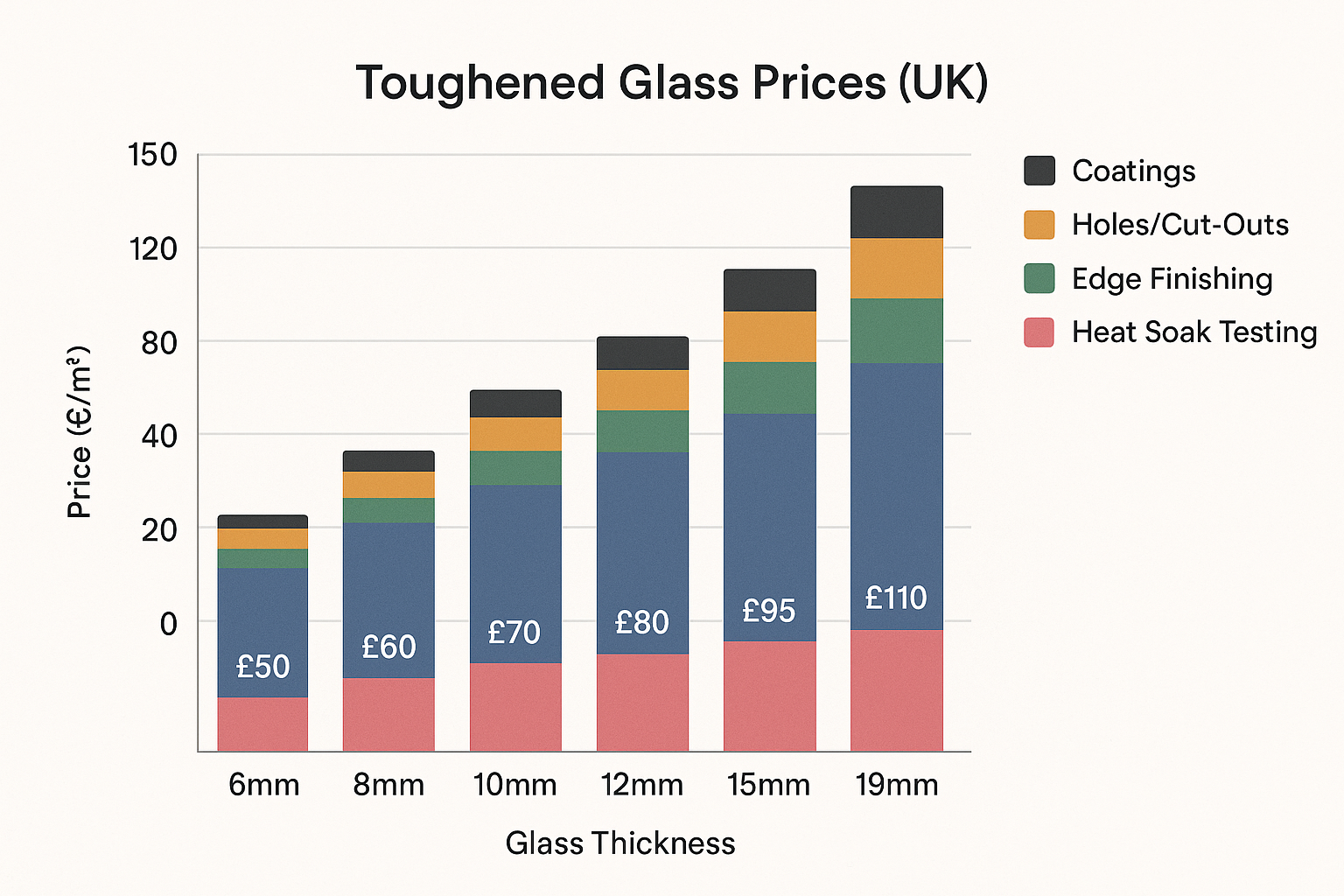

Cost Guide: Toughened Glass Prices UK

Understanding toughened glass costs helps with budgeting and specification decisions. Prices vary significantly based on thickness, size, treatments, and project scope, but we can provide general guidance based on current market rates.

Price Ranges Per Square Metre

Basic supply-only pricing for clear toughened glass (excludes installation, hardware, and framing):

6mm toughened glass: £45-75 per m²

- Suitable for smaller panels, shower screens, internal applications

- Minimum thickness for most toughened glass applications

8mm toughened glass: £65-95 per m²

- Common specification for internal doors, partitions, larger shower enclosures

- Good balance of performance and cost

10mm toughened glass: £85-120 per m²

- Standard specification for shop fronts, commercial entrance doors

- Suitable for larger panels with moderate wind loading

12mm toughened glass: £110-160 per m²

- Heavy-duty commercial applications, structural glazing

- Enhanced impact resistance and wind load performance

15mm toughened glass: £150-210 per m²

- High-performance applications, large-format glazing

- Balustrades, high-rise applications, prestigious projects

19mm toughened glass: £200-280 per m²

- Specialist structural applications, glass floors, heavy-duty balustrades

- Maximum thickness for most architectural toughened glass

These prices assume reasonable quantities (minimum 5-10m²), standard rectangular panels, and no unusual complexity. Small quantities, complex shapes, numerous holes, or rushed timescales increase costs.

Factors Affecting Cost

Glass Thickness: As shown above, cost roughly increases with thickness, though not linearly. The jump from 10mm to 12mm is proportionally smaller than from 6mm to 8mm.

Panel Size: Larger individual panels may incur surcharges due to handling complexity and increased breakage risk during manufacturing. Panels exceeding 3m x 2m often require specialist processing.

Shape and Complexity: Rectangular panels are standard. Shaped panels (curved edges, radius corners, complex profiles) require additional cutting and edge finishing, increasing cost by 15-40%.

Holes and Cut-outs: Each hole requires precise drilling with specialist equipment. Typical charges:

- Small holes (10-20mm diameter): £8-15 per hole

- Large holes (50-100mm diameter): £20-40 per hole

- Complex cut-outs or notches: £30-80 each depending on size

Edge Finishing: Edge quality affects both aesthetics and cost:

- Arrised edges (standard): included in base price

- Ground edges: +£8-15 per linear metre

- Polished edges: +£15-25 per linear metre

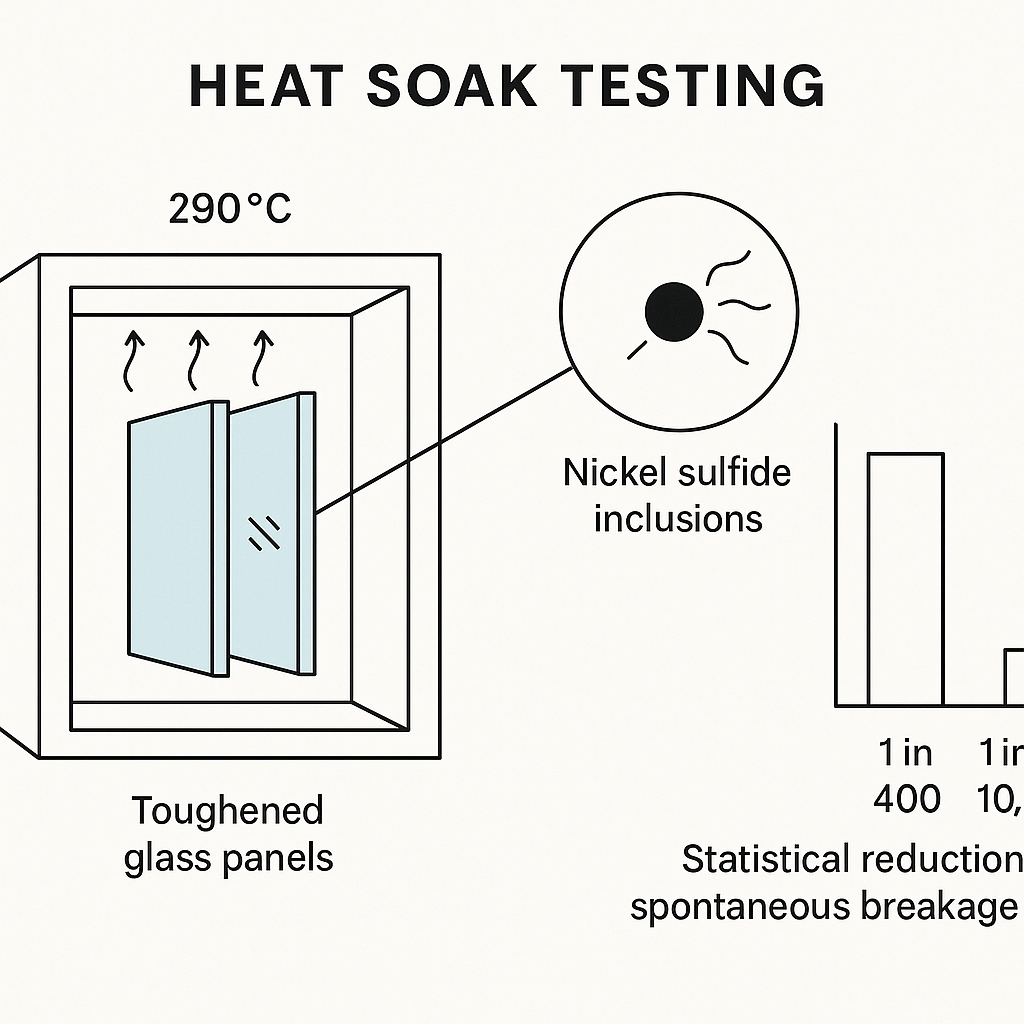

Heat Soak Testing: Adds approximately £30-50 per m² to the base glass cost. Essential for critical applications but optional for standard installations.

Coatings and Treatments: Specialty glazing adds cost:

- Low-emissivity (Low-E) coatings: +£15-30 per m²

- Solar control coatings: +£20-40 per m²

- Low-iron (ultra-clear) glass: +£30-60 per m²

- Acid-etched or sandblasted finishes: +£40-80 per m²

- Printed or colored glass: +£60-150 per m² depending on specification

Installation Costs

Supply-only pricing tells only part of the story. Installation adds significant cost depending on application:

Shop Front Installation: Complete installation including removal of existing glazing, frame preparation, glazing, and hardware typically costs £150-300 per m² depending on access, height, and complexity.

Commercial Door Installation: Including door hardware (closers, locks, panic devices, handles), expect £800-2,000 per door depending on specification and hardware quality.

Balustrade Installation: Structural glass balustrade installation is specialist work. Complete installed costs typically range from £400-800 per linear metre for base-fixed systems, £600-1,200 per linear metre for structurally glazed systems.

Shower Enclosure Installation: A complete custom toughened glass shower enclosure (supply and installation) typically costs £600-1,500 depending on size, configuration, and hardware quality.

When Heat Soak Testing Is Worth the Investment

At £30-50 per m², heat soak testing represents 20-40% additional glass cost. Is it worthwhile?

Definitely worthwhile for:

- Overhead glazing where breakage creates safety risk

- High-rise applications where replacement is expensive

- Critical operational environments (data centres, hospitals)

- High-profile architectural projects where breakage would be embarrassing

- Locations where broken glazing creates security vulnerabilities

Optional for:

- Ground-level shop fronts with replacement glass readily available

- Internal partitions where breakage creates minimal disruption

- Budget-sensitive projects where spontaneous breakage risk is acceptable

Generally unnecessary for:

- Small residential applications (shower screens, single doors)

- Temporary installations

- Applications with easy replacement access

The spontaneous breakage risk without heat soak testing is approximately 1 in 400-800 panels. For a project installing 100 panels, you might statistically expect breakage in 0-1 panels over the installation’s lifetime. Whether heat soak treatment is worthwhile depends on the consequences and costs of that potential breakage.

Advantages and Limitations

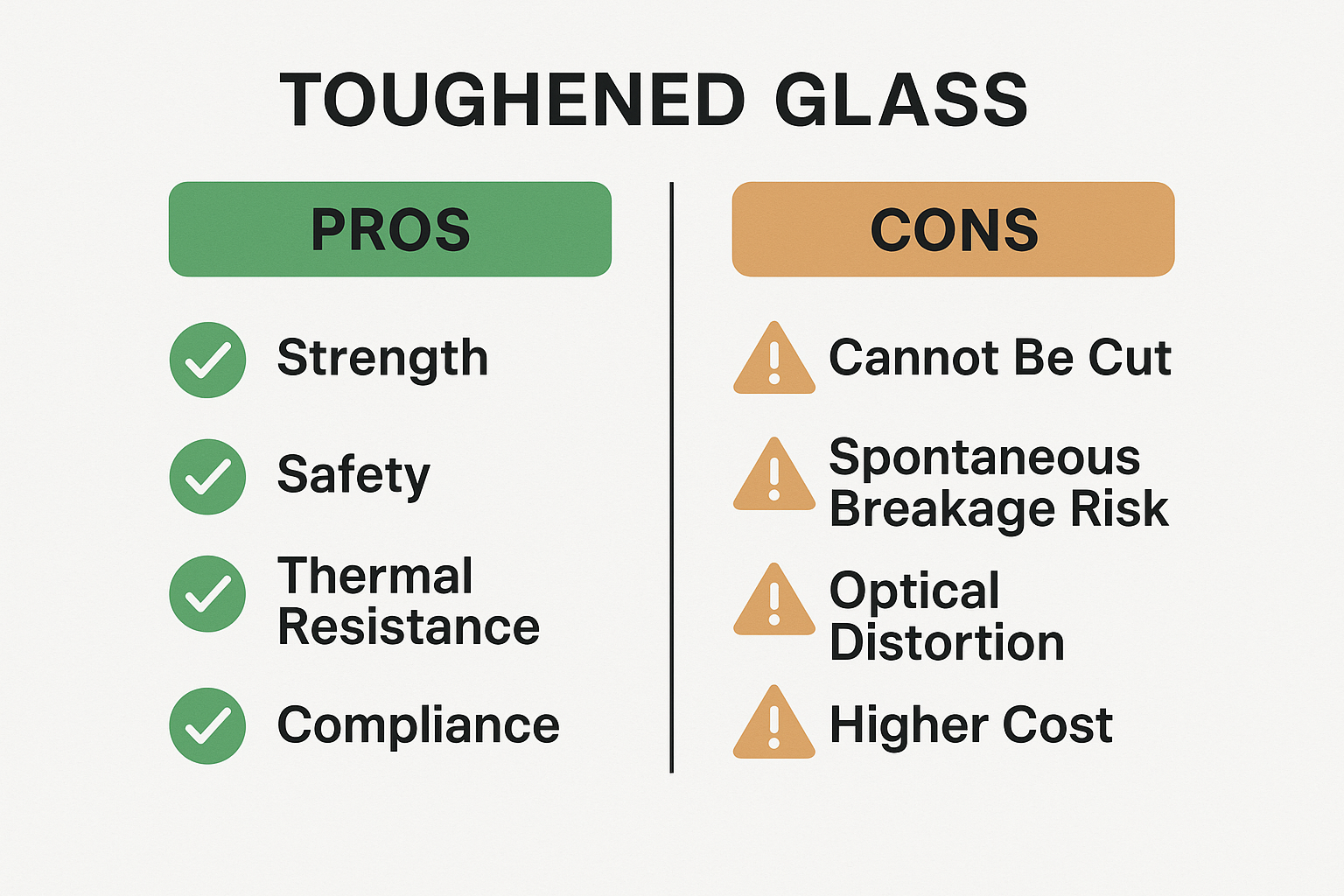

Like any building material, toughened glass offers distinct advantages and inherent limitations. Understanding both helps with informed specification decisions.

Advantages of Toughened Glass

Significantly Enhanced Strength: The primary benefit is strength. Toughened glass withstands 4-5 times greater impact force than equivalent annealed glass before breaking. This translates to dramatically reduced breakage risk in normal use.

Safe Breakage Pattern: When toughened glass does break, it disintegrates into thousands of small, relatively blunt pieces rather than large dangerous shards. This characteristic substantially reduces injury risk, which is why regulations mandate safety glazing in critical locations.

Thermal Stress Resistance: Toughened glass withstands temperature differentials approximately five times greater than annealed glass (approximately 200°C vs 40°C). This makes it suitable for applications involving heat exposure or rapid temperature changes.

Scratch Resistance: The tempering process creates a harder surface more resistant to scratching than annealed glass. In high-traffic commercial environments subject to cleaning and contact, this durability advantage maintains appearance over years of service.

Regulatory Compliance: Toughened glass meets UK Building Regulations requirements for safety glazing, providing straightforward compliance in critical locations. Specifying toughened glass eliminates regulatory concerns in doors, low-level glazing, and other mandated applications.

Wide Range of Applications: From delicate shower screens to robust structural glazing, toughened glass adapts to diverse applications. The variety of available thicknesses, sizes, and treatments makes it suitable for most architectural glazing needs.

Excellent Longevity: Properly manufactured and installed toughened glass provides decades of service without degradation. The installations we completed 20 years ago perform identically to new installations—there’s no weathering, fading, or deterioration.

Limitations of Toughened Glass

Cannot Be Modified After Tempering: This is perhaps the most significant limitation. Once glass is toughened, it cannot be cut, drilled, or edge-worked. All fabrication must be completed before tempering, demanding precise measurement and planning with no opportunity for on-site adjustment.

We’ve seen costly mistakes where contractors ordered toughened glass with incorrect measurements or forgot to specify necessary holes. The glass cannot be modified—it must be scrapped and reordered, causing delays and expense.

Risk of Spontaneous Breakage: Nickel sulfide inclusions can cause toughened glass to break spontaneously without external impact, sometimes months or years after installation. Whilst heat soak testing dramatically reduces this risk, it doesn’t eliminate it entirely, and heat soak treatment isn’t always specified.

This risk is relatively small (approximately 1 in 400-800 panels without heat soak treatment), but when it occurs, it creates disruption and requires replacement. For critical applications, this risk warrants heat soak testing or specification of laminated glass.

Optical Distortion: The rapid cooling process during tempering can create slight surface undulations or “roller wave” visible under certain lighting conditions. For most applications, this distortion is minimal and unnoticeable, but for applications requiring pristine optical quality, annealed glass may be preferred.

Higher Cost: Toughened glass costs significantly more than annealed glass of equivalent thickness. The thermal treatment process, quality control requirements, and handling complexity all contribute to increased cost. For budget-sensitive projects, this cost premium may influence specification decisions.

Limited Availability in Some Sizes: Very large panels or unusual sizes may have extended lead times or may not be available from all suppliers. The tempering process requires specialized equipment, and not all glass processors can handle every size or specification.

No Post-Breakage Protection: Once toughened glass breaks, it provides no further barrier function. For security applications or overhead glazing where post-breakage integrity matters, laminated glass may be more appropriate despite higher cost.

Frequently Asked Questions

Is toughened glass the same as tempered glass?

Yes, absolutely. Toughened glass and tempered glass are exactly the same product with identical manufacturing processes, strength characteristics, and safety properties. The terminology difference is purely regional—”toughened” is used in the UK and Europe, whilst “tempered” is the American term. Both refer to glass that has been thermally treated through heating and rapid cooling to increase strength and create safe breakage characteristics.

How can I tell if my existing glass is toughened?

Toughened glass must carry permanent markings in one corner showing compliance with safety standards. Look for “BS EN 12150” marking, manufacturer identification, and a safety glass symbol. These markings are usually etched or printed and remain visible throughout the glass’s life. If you can’t find these markings, the glass is likely annealed (standard) glass. You can also check with the original installer or building records.

Can toughened glass be cut to size after installation?

No, absolutely not. Toughened glass cannot be cut, drilled, or modified in any way after the tempering process. Any attempt to cut or drill toughened glass will cause the entire panel to shatter instantly into thousands of pieces. All sizing, holes, notches, and edge finishing must be completed before the glass enters the tempering furnace. This requires precise measurement and planning with no opportunity for on-site adjustments.

Why does toughened glass sometimes break spontaneously?

Spontaneous breakage occurs due to nickel sulfide inclusions—tiny impurities that can exist in the raw glass. These inclusions can change phase over time, creating internal stress that eventually exceeds the glass’s strength. This happens in approximately 1 in 400-800 panels without heat soak testing. Heat soak testing reduces this risk to approximately 1 in 10,000 panels by forcing any problematic inclusions to cause breakage during controlled testing rather than after installation.

Is toughened glass suitable for overhead glazing?

Toughened glass alone is not recommended for overhead glazing where people could be underneath. While toughened glass breaks safely into small pieces, these pieces still fall and could cause injury. UK Building Regulations typically require laminated glass for overhead applications to ensure fragments remain bonded to the interlayer if breakage occurs. However, toughened glass can be used as part of a laminated assembly for overhead glazing.

How much stronger is toughened glass than normal glass?

Toughened glass is approximately 4-5 times stronger than annealed (normal) glass of the same thickness. This means it can withstand much greater impact force, wind loading, and thermal stress before breaking. The exact strength increase depends on the glass thickness and tempering process, but the improvement is substantial across all applications.

Does toughened glass provide better security than normal glass?

Toughened glass is much harder to break than annealed glass, providing some security benefit. However, once broken, toughened glass provides no further resistance as it shatters completely. For high-security applications, laminated glass or toughened laminated glass is preferred because it maintains a barrier even after the glass fractures, making forced entry much more difficult.

Can toughened glass be used in double glazing?

Yes, toughened glass is commonly used in double-glazed units (IGUs). One or both panes can be toughened depending on the application requirements. This is standard practice for doors, large windows, and applications where safety glazing is required. The toughening process doesn’t affect the glass’s ability to be incorporated into insulated glass units.

How long does toughened glass last?

Properly manufactured and installed toughened glass can last indefinitely. Unlike some building materials, glass doesn’t degrade, fade, or weather over time. The installations we completed 20+ years ago perform identically to new installations. The only maintenance required is periodic cleaning. However, seals and hardware around the glass may need replacement over time.

Is heat soak testing necessary for all toughened glass?

Heat soak testing is not legally required but is recommended for critical applications. It’s particularly worthwhile for overhead glazing, high-rise applications, locations where replacement would be expensive or disruptive, and high-profile projects where spontaneous breakage would be problematic. For standard ground-level applications with easy replacement access, heat soak testing is optional but adds peace of mind.

Can I install toughened glass myself?

While possible for simple applications like shower screens with appropriate hardware, professional installation is recommended for most applications. Toughened glass is heavy, requires careful handling, and proper installation is critical for safety and performance. Commercial applications, structural glazing, and complex installations should always be professionally installed. Incorrect installation can void warranties and create safety risks.

Professional Installation and Service

Proper installation is crucial for toughened glass performance, safety, and longevity. While the glass itself is robust, incorrect installation can create stress concentrations, premature failure, and safety hazards.

Why Professional Installation Matters

Safety Considerations: Toughened glass panels are heavy and require specialized handling equipment. Large panels may weigh 50-100kg or more, demanding proper lifting equipment and multiple installers. Improper handling can cause injury or glass breakage.

Stress Management: Installation must avoid creating stress concentrations that could cause premature failure. This includes proper support, avoiding point loads, and ensuring thermal expansion allowances. Professional glaziers understand these requirements and install accordingly.

Weatherproofing: Proper sealing is essential for weather protection and thermal performance. Professional installation includes appropriate sealants, drainage provisions, and thermal breaks where required.

Compliance: Building Control approval may require professional installation certificates, particularly for structural glazing or critical safety applications. Professional installers provide necessary documentation and compliance certification.

Our Installation Process

Site Survey and Measurement: We begin with precise site measurement using laser measuring equipment. This eliminates measurement errors that could result in incorrectly sized glass requiring replacement.

Design and Specification: Our team reviews structural requirements, wind loading, thermal considerations, and regulatory compliance to ensure appropriate glass specification and installation details.

Manufacturing Coordination: We work directly with glass manufacturers to ensure correct specification, quality control, and delivery scheduling. Our relationships with suppliers ensure priority service and competitive pricing.

Professional Installation: Our certified glaziers use appropriate equipment and techniques for safe, compliant installation. This includes proper handling, stress-free mounting, and complete weatherproofing.

Quality Assurance: Every installation includes final inspection, testing where appropriate, and provision of compliance documentation. We stand behind our work with comprehensive warranties.

Maintenance and Aftercare

Toughened glass requires minimal maintenance, but proper care extends its life and maintains appearance:

Regular Cleaning: Use appropriate glass cleaners and avoid abrasive materials that could scratch the surface. For commercial applications, professional cleaning services ensure optimal appearance.

Seal Inspection: Periodically check weatherseals and glazing compounds for deterioration. Early replacement prevents water ingress and maintains thermal performance.

Hardware Maintenance: Door hardware, window mechanisms, and structural fixings require periodic inspection and maintenance to ensure continued safe operation.

Damage Assessment: Any chips, cracks, or damage should be professionally assessed immediately. While toughened glass is strong, damage can compromise its integrity.

Get Professional Toughened Glass Installation

Whether you’re planning a new shop front, replacing damaged glazing, or upgrading to safety glass for compliance, professional specification and installation ensure optimal results.

Huxley & Co – Your Toughened Glass Specialists

With over 20 years of experience serving businesses across London and the South East, we understand the critical role glazing plays in your property’s security, appearance, and compliance. Our qualified glaziers provide comprehensive services from initial consultation through professional installation and ongoing support.

Why Choose Huxley & Co for Your Toughened Glass Project?

Expert Specification: We help you select the right glass thickness, treatments, and specifications for your specific application, ensuring optimal performance and compliance.

Quality Suppliers: Our relationships with leading glass manufacturers ensure competitive pricing, quality products, and reliable delivery schedules.

Professional Installation: Our certified glaziers use proper equipment and techniques for safe, compliant installation that meets all relevant standards.

Comprehensive Service: From emergency repairs to complete shop front refurbishment, we handle every aspect of commercial and residential glazing.

Trusted by Leading Brands: We’ve completed projects for KFC, Boots, Nando’s, APM Monaco, and hundreds of independent businesses across the region.

Ready to Discuss Your Toughened Glass Requirements?

📞 Call: 0207 112 4849 (24/7 Emergency Line)

📧 Email: info@huxleyandco.co.uk

🌐 Online: Book Your Free Consultation

Service Areas: London, Essex, Kent, Surrey, Hertfordshire, and surrounding areas

Professional glazing services for commercial and residential properties

Related Articles:

- Roller Shutter Maintenance: The Ultimate UK Guide

- Roller Shutter Repairs: Common Problems and Solutions

- Cost of Shutters: Complete Pricing Guide

This guide is updated regularly to reflect current UK regulations, industry standards, and best practices. For specific advice about your glazing requirements, contact Huxley & Co for professional consultation and quotation.